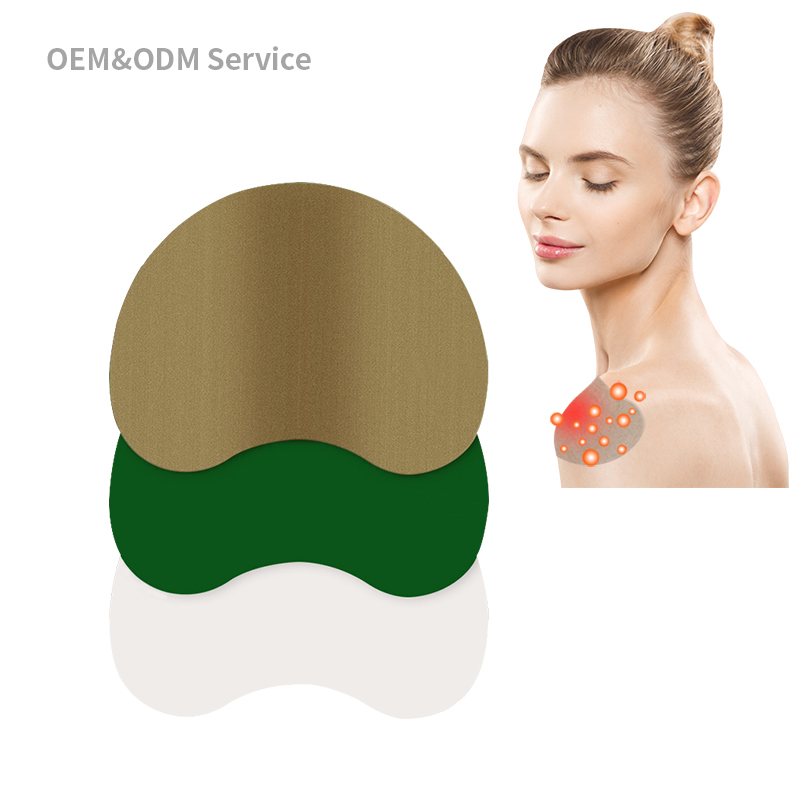

The Importance of Sustainability Practices in Shoulder Pain Patches OEM Production

In today's increasingly eco-conscious market, sustainability has become a critical factor in manufacturing processes across various industries, including healthcare. For a shoulder pain patches manufacturer, integrating sustainability practices into Original Equipment Manufacturer (OEM) production is not only an ethical obligation but also a strategic business move. This article delves into the importance of sustainability in shoulder pain patches OEM production, exploring the benefits, challenges, and future prospects of adopting eco-friendly practices. We will also address common questions related to sustainable manufacturing in this sector.

Understanding Sustainability in OEM Production

Sustainability in manufacturing refers to practices that do not deplete resources or harm ecological systems, ensuring long-term environmental health. For shoulder pain patches OEM production, this involves using sustainable materials, reducing waste, conserving energy, and ensuring that all processes comply with environmental regulations.

Benefits of Sustainability Practices in Shoulder Pain Patches OEM Production

Environmental Impact:

- Reduced Carbon Footprint: Sustainable practices, such as using renewable energy and optimizing production processes, significantly reduce the carbon footprint of shoulder pain patches manufacturing.

- Waste Minimization: Implementing waste reduction techniques ensures that manufacturing by-products are minimized, recycled, or disposed of responsibly.

Economic Advantages:

- Cost Savings: Energy-efficient processes and waste reduction can lead to substantial cost savings in the long term. Sustainable materials may also reduce the need for expensive waste management solutions.

- Market Competitiveness: Eco-friendly products are increasingly favored by consumers, providing a competitive edge for manufacturers who prioritize sustainability.

Regulatory Compliance:

- Adherence to Standards: Meeting environmental regulations helps avoid legal issues and potential fines. Compliance with standards like ISO 14001 demonstrates a commitment to environmental management.

- Future-Proofing: As regulations become stricter, early adoption of sustainable practices positions manufacturers to adapt easily to future requirements.

Brand Reputation:

- Consumer Trust: Demonstrating a commitment to sustainability builds consumer trust and loyalty. Customers are more likely to support brands that prioritize environmental responsibility.

- Stakeholder Confidence: Investors and stakeholders increasingly consider sustainability as a key factor in decision-making. Sustainable practices can attract investment and support.

Implementing Sustainable Practices in OEM Production

Sustainable Materials:

- Biodegradable Components: Using biodegradable materials for shoulder pain patches helps reduce environmental impact. These materials break down naturally, minimizing pollution.

- Recycled Materials: Incorporating recycled materials in packaging and production reduces the need for virgin resources and supports recycling initiatives.

Energy Efficiency:

- Renewable Energy: Utilizing solar, wind, or other renewable energy sources can power manufacturing facilities, reducing reliance on fossil fuels.

- Energy-Efficient Equipment: Investing in energy-efficient machinery and optimizing production schedules can lower energy consumption.

Waste Management:

- Recycling Programs: Establishing robust recycling programs for materials used in production helps minimize waste.

- Waste-to-Energy: Converting waste into energy is an innovative way to reduce waste and generate renewable energy.

Sustainable Packaging:

- Eco-Friendly Packaging: Using sustainable packaging materials, such as recycled cardboard or biodegradable plastics, reduces environmental impact.

- Minimalist Design: Reducing packaging size and materials used can decrease waste and transportation emissions.

Water Conservation:

- Efficient Water Use: Implementing water-saving technologies and recycling water used in production processes helps conserve this vital resource.

- Water Treatment: Treating wastewater before disposal ensures that harmful contaminants do not enter the environment.

Challenges in Implementing Sustainability Practices

High Initial Costs:

- Implementing sustainable technologies and materials often requires significant upfront investment. However, these costs can be offset by long-term savings and increased market competitiveness.

Supply Chain Complexity:

- Ensuring that all suppliers and partners adhere to sustainability standards can be challenging. It requires rigorous vetting and ongoing monitoring.

Consumer Perception:

- While many consumers prefer sustainable products, others may be unwilling to pay a premium for them. Educating consumers about the benefits of sustainability is crucial.

Regulatory Variability:

- Different markets have varying environmental regulations, making it complex for manufacturers to maintain compliance across regions.

Future Trends in Sustainable OEM Production

Innovative Materials:

- The development of new sustainable materials, such as plant-based polymers and nanomaterials, will revolutionize shoulder pain patches production.

Circular Economy:

- Moving towards a circular economy, where products are designed to be reused, repaired, or recycled, will further enhance sustainability in manufacturing.

Advanced Technologies:

- The use of advanced technologies like blockchain for supply chain transparency and AI for optimizing resource use will support sustainable practices.

Consumer-Driven Demand:

- As consumer awareness and demand for sustainable products grow, manufacturers will increasingly prioritize sustainability to meet market expectations.

Frequently Asked Questions

What are the key benefits of sustainable practices in shoulder pain patches OEM production?

- Benefits include reduced environmental impact, cost savings, enhanced market competitiveness, regulatory compliance, and improved brand reputation.

How can a shoulder pain patches manufacturer implement sustainable practices?

- Implementing sustainable materials, energy-efficient processes, robust waste management, eco-friendly packaging, and water conservation are key strategies.

What challenges do manufacturers face in adopting sustainable practices?

- Challenges include high initial costs, supply chain complexity, varying consumer perceptions, and regulatory variability.

How does sustainability impact the competitiveness of shoulder pain patches suppliers?

- Sustainability enhances market competitiveness by appealing to eco-conscious consumers, reducing operational costs, and ensuring regulatory compliance.

What future trends are expected in sustainable OEM production?

- Future trends include the development of innovative materials, a shift towards a circular economy, the adoption of advanced technologies, and increasing consumer-driven demand for sustainable products.

By prioritizing sustainability, shoulder pain patches manufacturers and suppliers can not only contribute to environmental preservation but also enhance their business prospects. Sustainable practices lead to cost savings, regulatory compliance, and increased consumer trust, positioning companies for long-term success in the healthcare market.