How Do I Ensure the Quality of Custom Cooling Pain Relief Patches?

Ensuring the quality of your Custom Cooling Pain Relief Patches is crucial to not only delivering effective pain relief but also protecting your brand's reputation in a competitive market. With the growing demand for pain relief solutions, particularly in the form of cooling patches, the need for high-quality products has never been more critical. Whether you are working with a Cooling Pain Relief Patches Manufacturer, a Cooling Pain Relief Patches OEM, or a Private Label Cooling Pain Relief Patches Supplier, there are several key steps to follow to ensure that your product meets the highest standards of safety, efficacy, and consumer satisfaction. This article will provide you with a comprehensive guide on how to guarantee the quality of your Cooling Pain Relief Patches from the design phase to the final product.

1. The Importance of Quality in Custom Cooling Pain Relief Patches

Quality is essential in any product, but especially for something like Cooling Pain Relief Patches, which directly interacts with the skin and delivers active ingredients to relieve pain. Low-quality patches can lead to poor adhesion, skin irritation, or even ineffectiveness, which can harm your brand’s reputation and customer trust. Here’s why quality control should be a priority:

- Safety Concerns: Patches that are poorly manufactured can cause adverse reactions, such as rashes, burns, or allergic reactions.

- Effectiveness: A Custom Cooling Pain Relief Patch must effectively deliver cooling and soothing relief for pain. Poorly formulated patches may not offer the desired relief, leading to customer dissatisfaction.

- Brand Integrity: Consistently high-quality products build a strong reputation. Your customers will associate your brand with reliability and effectiveness.

Ensuring top-quality Cooling Pain Relief Patches guarantees that your product performs as expected, builds customer trust, and positions your brand as a leader in the market.

2. Working with a Trusted Cooling Pain Relief Patches Manufacturer

The first step in ensuring quality is choosing the right Cooling Pain Relief Patches Manufacturer or Cooling Pain Relief Patches Supplier. Not all manufacturers are equal, and selecting a reputable supplier is vital to the success of your product.

a) Manufacturing Standards and Certifications

Choose a manufacturer that adheres to internationally recognized standards for production and safety. Look for certifications such as Good Manufacturing Practices (GMP) or ISO certifications. These certifications ensure that the manufacturer follows stringent processes to maintain quality at every stage of production. It is also essential that the manufacturer meets local regulatory requirements for skin-contact products, especially when it comes to the ingredients used in the patch.

b) Experience and Expertise

A reliable Cooling Pain Relief Patches OEM partner should have experience in producing similar products. They should understand the complexities of creating patches that are not only effective but also comfortable and safe for long-term use. They should also be familiar with different types of adhesives, backing materials, and cooling agents, which are crucial components in producing a high-quality patch.

c) Track Record and Reputation

Research the manufacturer's reputation in the industry. Look for reviews and testimonials from other businesses that have worked with them. A Cooling Pain Relief Patches Supplier with a solid track record will be more likely to deliver consistent, high-quality results. Ask for references or case studies from past clients who have worked on Private Label Cooling Pain Relief Patches.

3. Selecting the Right Materials for Custom Cooling Pain Relief Patches

The materials used in your Custom Cooling Pain Relief Patches are crucial in determining their quality and effectiveness. These materials should not only be safe and hypoallergenic but should also enhance the cooling and pain-relieving effects of the patch.

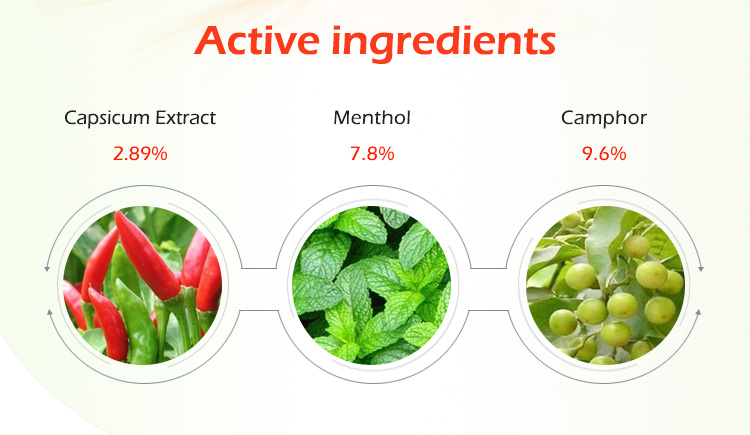

a) Cooling Agents

Cooling agents such as menthol, camphor, or methyl salicylate are commonly used in Cooling Pain Relief Patches for their soothing properties. Ensure that your manufacturer uses high-quality, effective ingredients and adheres to the correct concentration to avoid potential skin irritation or ineffective relief. A trusted Cooling Pain Relief Patches OEM will know the proper formulations to use based on scientific research.

b) Adhesives and Backing Materials

The adhesive used in your patches should be skin-friendly and capable of providing strong adhesion without causing irritation. The backing material must be flexible and breathable, ensuring that the patch stays in place while allowing the skin to breathe. These factors are essential to maintaining comfort throughout the duration of use.

c) Ingredients Transparency

Ensure that your Cooling Pain Relief Patches Supplier provides full transparency regarding the ingredients used. Opt for suppliers that use natural, non-toxic materials and are open about their sourcing and formulation processes. This transparency not only helps ensure quality but also appeals to consumers who are increasingly seeking clean, natural products.

4. Testing and Quality Assurance Procedures

Once you’ve selected your Cooling Pain Relief Patches Manufacturer, the next step is ensuring that rigorous testing and quality assurance (QA) procedures are in place. These procedures guarantee that the final product meets the standards for safety, effectiveness, and performance.

a) Prototype Testing

Before moving to full-scale production, request prototypes of your Custom Cooling Pain Relief Patches to assess their quality. Testing the prototype allows you to check for issues such as:

- Proper adhesion and fit

- Cooling effect and duration

- Skin irritation or allergic reactions

Testing prototypes is essential to refine the product before committing to large-scale production. You can also gather feedback from focus groups or potential customers to evaluate the overall user experience.

b) Batch Testing

During production, the manufacturer should conduct regular batch testing to ensure that each batch of patches meets the required standards. This includes testing the active ingredients for consistency, the adhesive strength, and the patch’s overall integrity. Batch testing also ensures that there are no deviations in the quality of materials used, which could affect the effectiveness or safety of the patch.

c) Final Product Inspection

Before shipping, a final inspection should be conducted to ensure that each Private Label Cooling Pain Relief Patch meets the brand’s quality standards. The inspection process should include evaluating the packaging, labeling, and expiration dates, as well as confirming that the patches are properly sealed and ready for use.

5. Regulatory Compliance and Safety Standards

For any Custom Cooling Pain Relief Patches, compliance with local and international regulations is a must. Ensure that the Cooling Pain Relief Patches Manufacturer adheres to the appropriate regulations for consumer safety, such as the U.S. FDA or European Medicines Agency (EMA) standards, especially if the patches contain active medicinal ingredients.

a) Skin Sensitivity Testing

Conduct dermatological testing to ensure that your Cooling Pain Relief Patches are safe for all skin types. The patch should be hypoallergenic, free from harmful chemicals, and designed to minimize irritation. Conduct patch tests to confirm that the product is safe for prolonged skin contact.

b) Labeling and Instructions

Make sure that the Cooling Pain Relief Patches OEM partner provides clear and accurate labeling for the product. This includes proper usage instructions, ingredient list, any potential side effects, and allergy information. Proper labeling not only enhances safety but also builds customer trust.

6. Final Thoughts on Ensuring Quality

To ensure the quality of your Custom Cooling Pain Relief Patches, it’s important to carefully choose a reliable manufacturer, select quality materials, and implement thorough testing and quality control measures. By partnering with a reputable Cooling Pain Relief Patches Supplier and overseeing the production process closely, you can guarantee that your product is both safe and effective. Quality control is an ongoing process, and by staying involved in every stage, from design to production to testing, you can ensure that your Cooling Pain Relief Patches are the best they can be, ultimately delivering value to your customers and strengthening your brand.

Frequently Asked Questions (FAQ)

Q1: How can I ensure the quality of my Custom Cooling Pain Relief Patches?

You can ensure quality by selecting a reliable Cooling Pain Relief Patches Manufacturer, choosing high-quality materials, conducting prototype and batch testing, and ensuring regulatory compliance.

Q2: What materials are important for high-quality Cooling Pain Relief Patches?

The most important materials include skin-friendly adhesives, breathable backing materials, and effective cooling agents such as menthol or camphor.

Q3: How can I verify the safety of my Cooling Pain Relief Patches?

Safety can be verified by conducting dermatological testing and ensuring the patches meet the required regulatory standards for skin contact products.

Q4: What certifications should a Cooling Pain Relief Patches Manufacturer have?

Look for manufacturers with ISO certifications or Good Manufacturing Practices (GMP) certifications to ensure they follow high-quality production processes.

Q5: Is testing important for Custom Cooling Pain Relief Patches?

Yes, testing is critical to ensure the patch delivers effective pain relief, adheres properly to the skin, and does not cause irritation or allergic reactions.

By following these steps and ensuring that quality is built into every aspect of the production process, your Custom Cooling Pain Relief Patches will not only provide effective relief but also reinforce your brand’s commitment to safety and consumer satisfaction.