How Analgesic Patches OEM Can Help Improve Your Productivity

In today’s competitive business environment, maximizing productivity is crucial for staying ahead. Whether you're a healthcare provider, retailer, or wellness brand, increasing operational efficiency can significantly enhance your bottom line. One of the most effective ways to boost productivity in your business is by partnering with an Analgesic Patches OEM (Original Equipment Manufacturer).

This partnership can lead to significant improvements in production, product quality, time-to-market, and overall business operations. By working with a reliable Analgesic Patches Manufacturer, businesses gain access to expert manufacturing capabilities, customizable solutions, and scalable options that streamline operations. This article explores how partnering with an Analgesic Patches OEM can directly improve your productivity, reduce costs, and enhance your business’s operational efficiency.

1. Streamlined Manufacturing Processes

One of the key benefits of working with an Analgesic Patches OEM is the ability to streamline the manufacturing process. Manufacturing pain relief patches requires specialized equipment, highly trained staff, and adherence to strict quality standards. For many businesses, setting up an in-house manufacturing facility to produce Analgesic Patches would be both costly and inefficient.

By partnering with an established Analgesic Patches Supplier, your business can leverage their advanced manufacturing infrastructure, reducing the need for capital investment in machinery and labor. The OEM partner handles the entire manufacturing process—from sourcing raw materials to quality control—ensuring a smooth and efficient operation that frees up your team to focus on core business functions like marketing and sales.

Furthermore, many Analgesic Patches Manufacturers are equipped with the latest technology, ensuring that production lines are efficient and that products are created quickly without sacrificing quality. This reduces manufacturing time and increases overall productivity.

2. Cost Savings and Economies of Scale

Another significant way an Analgesic Patches OEM can help improve productivity is by providing cost savings through economies of scale. Large-scale manufacturers can produce Analgesic Patches at a much lower cost than smaller businesses, which can be passed on to you as a partner. These cost savings can then be reinvested into other areas of your business, such as marketing, product development, or customer service.

Outsourcing production to an Analgesic Patches Supplier also eliminates the need for businesses to manage raw material procurement, inventory, and logistics. As a result, you can focus more on building brand equity and expanding your market reach while leaving the manufacturing complexities to your trusted partner. This business model reduces overhead, saves valuable time, and allows your team to be more productive and agile.

3. Faster Time-to-Market

In the fast-paced wellness and healthcare markets, being able to quickly deliver products to consumers is a key factor in staying competitive. By partnering with an Analgesic Patches Manufacturer, businesses benefit from faster production times, allowing products to hit the shelves sooner.

OEMs typically have established production lines and logistics systems that can meet tight deadlines. This allows you to avoid the long lead times associated with setting up your own production processes. Whether you're launching a new product or expanding an existing line, Custom Analgesic Patches manufactured by an experienced OEM will ensure that your business can quickly respond to market demand without delays.

Additionally, the speed at which you can introduce new Private Label Analgesic Patches can enhance your brand’s agility, helping you stay ahead of competitors and meet changing customer preferences. By reducing the time-to-market, your business can quickly capitalize on new trends and consumer demands, improving productivity and revenue generation.

4. Flexibility and Customization

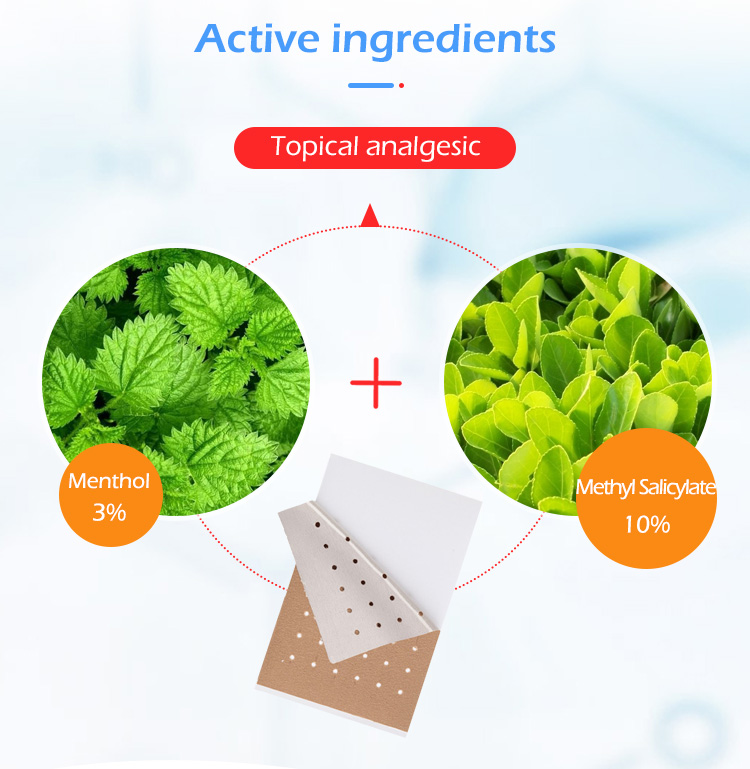

A major advantage of partnering with an Analgesic Patches OEM is the flexibility to customize your products according to your unique business needs. Whether you need specific Custom Analgesic Patches with tailored ingredients, packaging, or design, working with an OEM allows you to create a product that perfectly fits your brand’s identity.

Customization is essential for differentiation in the competitive pain relief market. It enables your business to cater to niche segments, offer specialized solutions (such as patches for muscle pain, joint relief, or herbal formulas), and develop products that resonate with your target market. The ability to provide Private Label Analgesic Patches further enhances your brand’s offerings, making it easier to scale your business and reach more customers.

The flexibility to make adjustments on the fly ensures that your business can quickly adapt to market changes, helping your team remain productive and responsive in a dynamic industry.

5. Access to Industry Expertise and Best Practices

When you partner with an experienced Analgesic Patches Supplier, you gain access to their industry expertise and best practices. Analgesic Patches Manufacturers are specialists in formulating, testing, and producing pain relief patches, meaning they have in-depth knowledge of the most effective ingredients, production techniques, and compliance regulations.

This expertise can lead to a more efficient product development process, as the OEM partner already understands the complexities involved in creating safe, effective products. As a result, your business can benefit from higher-quality products that meet all necessary regulatory standards without the need for extensive internal research and development. The result is a streamlined workflow that improves overall productivity.

Moreover, the OEM partner can provide insights into emerging trends, innovative delivery methods, and consumer preferences, allowing your business to stay ahead of the curve while saving valuable time on market research.

6. Quality Control and Consistency

Ensuring consistent quality across all products is crucial for maintaining customer satisfaction and building brand loyalty. Analgesic Patches OEM partners are equipped with the latest quality control systems, ensuring that each batch of analgesic patches meets the highest standards of safety and efficacy.

By relying on an experienced Analgesic Patches Supplier, your business can be confident that all products will meet the same high quality, reducing the risk of returns, complaints, or recalls. The consistency provided by your OEM partner allows your team to focus on other aspects of the business, such as marketing, sales, and customer engagement, rather than dealing with quality control issues or product failures.

This focus on quality ensures that your business maintains a strong reputation, which in turn drives repeat sales and long-term customer relationships. The time saved on dealing with quality issues can be redirected into more productive activities, helping your business grow.

7. Risk Mitigation and Compliance

Working with a trusted Analgesic Patches Manufacturer helps mitigate the risks associated with product development, manufacturing, and distribution. Analgesic Patches OEM partners have established processes for managing regulatory compliance, ensuring that your products meet all necessary industry standards and legal requirements.

For businesses new to the pain relief market, navigating regulatory requirements and ensuring compliance with health and safety standards can be complex and time-consuming. By outsourcing this responsibility to an experienced OEM, your business can focus on sales and brand development while the OEM partner ensures that the products are compliant with all necessary regulations, including those related to ingredients, manufacturing processes, and labeling.

This reduces the risk of costly delays, legal issues, or product recalls, which could otherwise detract from your productivity and reputation. The peace of mind provided by an experienced OEM partner allows your team to stay focused on driving business growth.

Conclusion

In conclusion, partnering with an Analgesic Patches OEM offers numerous advantages that can significantly improve your business’s productivity. From streamlined manufacturing processes and cost savings to faster time-to-market and customized product offerings, working with a reliable Analgesic Patches Supplier enhances your ability to scale and compete in the growing pain relief market. By leveraging the expertise and capabilities of an OEM, you can reduce operational complexities, minimize risks, and focus on what matters most—growing your business.

Frequently Asked Questions (FAQs)

1. How can an Analgesic Patches OEM improve my productivity?

By handling the manufacturing process, reducing production costs, and ensuring quality and compliance, an Analgesic Patches OEM allows your team to focus on marketing, sales, and business development, leading to increased productivity and efficiency.

2. What are Custom Analgesic Patches, and how do they benefit my business?

Custom Analgesic Patches are pain relief patches tailored to your specific brand needs, including ingredients, packaging, and design. They help differentiate your products in a competitive market and cater to the unique preferences of your target customers.

3. What are Private Label Analgesic Patches?

Private Label Analgesic Patches are pre-manufactured patches that you can rebrand as your own. This model allows your business to offer high-quality products without investing in production, reducing time and cost while expanding your product range.

4. How do I choose the right Analgesic Patches Supplier?

Look for an Analgesic Patches Supplier with a proven track record in quality control, compliance, and innovation. Consider factors like production capabilities, customization options, and customer service when selecting an OEM partner.

5. Can working with an OEM help reduce risks in manufacturing?

Yes, partnering with an experienced Analgesic Patches Manufacturer reduces risks by ensuring compliance with regulations, managing quality control, and providing consistent, high-quality products that meet industry standards.