Why Is OEM Quality So Important for Inflammation Relief Patches?

Understanding the Critical Role of Quality in OEM Manufacturing for Effective and Safe Products

Inflammation relief patches have become a trusted solution for millions seeking fast and localized pain management. As the market for these products expands rapidly, businesses must carefully select their production partners. One of the most crucial factors that determine product success and consumer trust is OEM quality. When working with an Inflammation Relief Patches Manufacturer or an Inflammation Relief Patches OEM partner, quality is not just a buzzword—it is the foundation of product efficacy, safety, and brand reputation.

This article delves into why OEM quality matters profoundly in the inflammation relief patch industry, particularly for companies exploring Custom Inflammation Relief Patches or Private Label Inflammation Relief Patches. We will analyze how quality impacts manufacturing, compliance, customer satisfaction, and ultimately, business success.

1. What Does OEM Quality Mean in the Context of Inflammation Relief Patches?

In the realm of OEM manufacturing, quality refers to the strict adherence to industry standards and best practices throughout the entire production process—from raw material sourcing and formulation to patch fabrication, packaging, and delivery. For an Inflammation Relief Patches Manufacturer, quality means:

Using premium, tested, and traceable ingredients

Following Good Manufacturing Practices (GMP) or ISO certifications

Ensuring precise formulation and dosage consistency

Employing advanced manufacturing technology for uniform patch adhesion and release

Performing rigorous quality control tests at every production stage

Packaging that preserves product integrity and complies with regulatory requirements

2. Why OEM Quality Is Crucial for Inflammation Relief Patches

a. Product Efficacy and Consumer Safety

The primary purpose of an inflammation relief patch is to provide targeted pain relief safely and effectively. Poor quality patches can result in inconsistent drug delivery, weak adhesion, skin irritation, or even allergic reactions. An Inflammation Relief Patches OEM partner with stringent quality protocols ensures that every batch delivers the promised therapeutic effect, enhancing user satisfaction and safety.

b. Regulatory Compliance and Market Access

Healthcare and wellness products must meet strict regulatory standards (such as FDA, CE, or local health authorities). High-quality OEM manufacturing guarantees compliance with these laws, preventing costly recalls or legal issues. An experienced Inflammation Relief Patches Manufacturer will assist in navigating compliance, including ingredient restrictions, labeling laws, and testing requirements.

c. Brand Reputation and Consumer Trust

In a competitive market, brand reputation hinges on delivering consistent, reliable products. Inferior quality patches can damage a brand’s credibility, leading to negative reviews and lost customers. Choosing an OEM supplier with a proven track record ensures that your Custom Inflammation Relief Patches or Private Label Inflammation Relief Patches maintain high standards and build loyal customer bases.

d. Long-term Cost Efficiency

While high-quality OEM manufacturing may have a higher upfront cost, it significantly reduces the risk of product returns, complaints, or regulatory fines. This saves money and time in the long run, allowing brands to focus on growth rather than crisis management.

e. Innovation and Customization Opportunities

Top-tier Inflammation Relief Patches OEM manufacturers invest in R&D, enabling innovative product features such as controlled release, multi-ingredient formulas, and skin-friendly adhesives. Quality-focused partners provide customized solutions that meet specific consumer needs and differentiate your brand in the marketplace.

3. Key Quality Factors in OEM Inflammation Relief Patch Manufacturing

i. Ingredient Sourcing and Testing

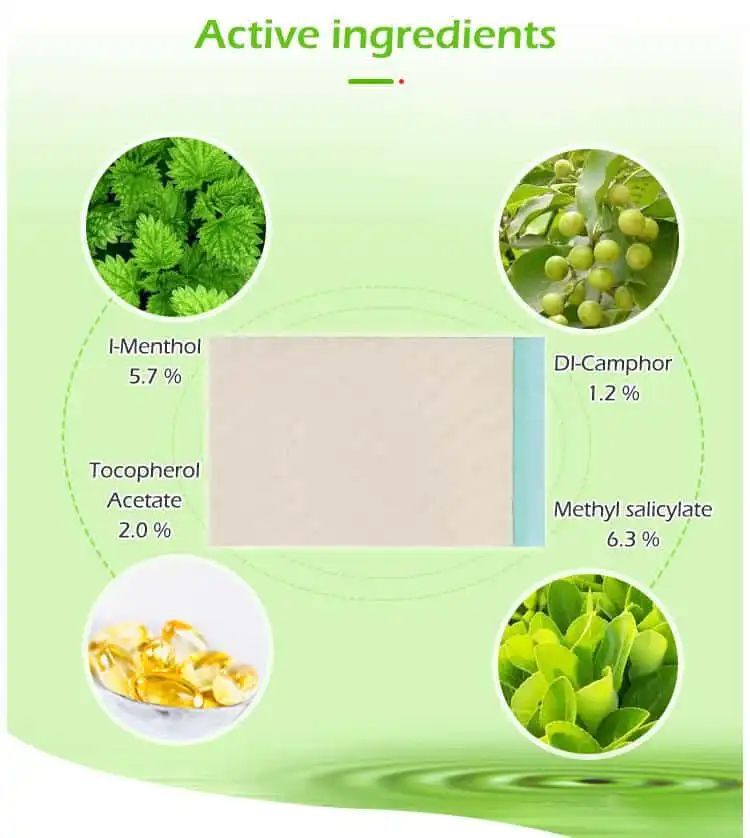

The base ingredients—herbs, analgesics, or pharmaceuticals—must be sourced from certified suppliers and tested for purity, potency, and contaminants. This ensures safety and efficacy.

ii. Formulation Consistency

Every patch must contain an exact dosage of active ingredients. OEM manufacturers use precise blending and dispensing technologies to achieve uniformity.

iii. Patch Design and Adhesion Quality

Patch materials, size, and adhesives affect comfort and wear time. High-quality manufacturers use hypoallergenic adhesives that balance strong skin adhesion with painless removal.

iv. Sterility and Hygiene Controls

Cleanroom environments and sterilization processes minimize contamination risk during production.

v. Packaging Integrity

OEM partners employ moisture-resistant, tamper-proof packaging that protects patches throughout shipping and storage.

vi. Batch Testing and Traceability

Routine testing on every batch for weight, adhesion, active ingredient concentration, and microbial contamination enables traceability and quality assurance.

4. OEM Quality vs. Private Label: What You Should Know

While both OEM and Private Label Inflammation Relief Patches Suppliers focus on quality, OEM manufacturers often have more control and responsibility over product formulation and manufacturing precision. Private label suppliers provide ready-made products with quality assurances but limited ability to customize.

Choosing an OEM partner means a stronger emphasis on quality controls tailored to your specific product vision. Private label options may offer speed and lower cost but at the expense of customization and possibly the highest quality standards.

5. How to Select a High-Quality Inflammation Relief Patches OEM Partner

Check Certifications: Ensure the manufacturer holds GMP, ISO, or other relevant certifications.

Review Manufacturing Capabilities: Ask about technology, cleanroom standards, and quality control processes.

Request Sample Testing: Obtain product samples for third-party lab testing.

Verify Ingredient Sourcing: Confirm traceability of raw materials.

Assess Experience: Choose manufacturers specializing in inflammation relief or topical pain patches.

Understand Compliance Support: The OEM should guide you through local and international regulations.

Evaluate Customer Feedback: Look for testimonials from other brands.

6. The Business Impact of OEM Quality

Brands that prioritize OEM quality gain:

Market credibility leading to higher sales

Reduced returns and complaints

Easier regulatory approvals

Greater flexibility in product innovation

Better consumer loyalty and repeat purchases

These factors collectively contribute to sustainable growth and profitability.

Related Questions and Short Answers

Q1: What is the difference between an Inflammation Relief Patches Manufacturer and an OEM?

A: An OEM is a type of manufacturer specializing in customized products designed to client specifications, while manufacturers may also offer standard products.

Q2: Why is quality control critical for Custom Inflammation Relief Patches?

A: Because customized products need consistent formulation and safety to protect consumers and comply with regulations.

Q3: Can Private Label Inflammation Relief Patches match OEM quality?

A: They can offer good quality but usually lack customization and may not have the same rigorous control over formulation.

Q4: How can I verify an OEM supplier’s quality standards?

A: Request certificates, visit manufacturing sites if possible, and review testing protocols and documentation.

Q5: Does higher OEM quality always mean higher costs?

A: Usually yes, but it also reduces risks and long-term costs associated with product failure or regulatory issues.

Q6: Are there quality certifications specific to inflammation relief patches?

A: Not specific to patches, but GMP, ISO, FDA registration, and CE certification are commonly required.

Q7: How does OEM quality affect regulatory compliance?

A: Higher OEM quality ensures all manufacturing steps meet regulatory standards, reducing risk of non-compliance.