The Importance of Quality Control in Herbal Pain Relief Patches OEM Manufacturing

In the competitive world of healthcare and wellness, ensuring the quality of products is paramount. This is particularly true in the manufacturing of herbal pain relief patches, where effectiveness and safety are directly tied to the quality of ingredients and production processes. For companies looking to partner with an Herbal Pain Relief Patches OEM, understanding the importance of quality control is crucial. This article will delve into why quality control is essential in Herbal Pain Relief Patches OEM manufacturing, how it impacts the reputation of a brand, and what measures should be in place to ensure the highest standards are met.

1. Ensuring Consistency and Efficacy in Products

One of the most critical aspects of quality control in Herbal Pain Relief Patches OEM manufacturing is ensuring consistency in the final product. For any Herbal Pain Relief Patches Manufacturer, maintaining a uniform quality in each batch produced is essential. This consistency ensures that customers receive the same level of pain relief with every use, which builds trust in the product and the brand.

Quality control processes, such as rigorous testing of raw materials and regular checks during the manufacturing process, help in maintaining this consistency. When partnering with a reliable Herbal Pain Relief Patches Supplier, businesses can be confident that the Custom Herbal Pain Relief Patches they offer will meet the expectations of their customers every time.

2. Meeting Regulatory Compliance and Safety Standards

Herbal pain relief patches, like any other healthcare product, must meet specific regulatory standards to be legally sold in the market. Quality control plays a crucial role in ensuring that these products are compliant with regulations, such as those set by the FDA or other relevant bodies.

A reputable Herbal Pain Relief Patches OEM will have stringent quality control measures in place to ensure that all products meet the necessary safety and efficacy standards. This includes testing for the correct concentration of active ingredients, ensuring the patches are free from contaminants, and verifying that they are safe for use on the skin. By choosing an Herbal Pain Relief Patches Manufacturer with robust quality control processes, brands can avoid costly recalls and potential legal issues.

3. Enhancing Brand Reputation and Customer Loyalty

The quality of a product is directly linked to a brand’s reputation. When a brand offers high-quality Herbal Pain Relief Patches, it not only meets customer expectations but also builds trust and loyalty. Conversely, poor quality products can lead to negative reviews, customer dissatisfaction, and damage to the brand’s reputation.

Partnering with a quality-focused Herbal Pain Relief Patches OEM allows brands to offer products that are not only effective but also reliable. This is especially important for companies looking to create Private Label Herbal Pain Relief Patches, where the brand’s name is directly associated with the product’s performance. A strong commitment to quality control ensures that the brand can confidently market its products as safe, effective, and trustworthy.

4. Reducing Costs Through Prevention of Defects

Quality control in Herbal Pain Relief Patches OEM manufacturing is not just about ensuring product quality; it’s also about cost efficiency. Defects and inconsistencies in products can lead to significant financial losses due to wasted materials, production delays, and the need for rework. In the worst cases, defective products reaching the market can result in expensive recalls and damage to the brand’s reputation.

By implementing robust quality control measures, Herbal Pain Relief Patches Manufacturers can identify and address potential issues early in the production process, preventing defects before they occur. This proactive approach not only saves costs but also ensures that the final product meets the highest standards of quality.

5. Customization and Quality Control: A Delicate Balance

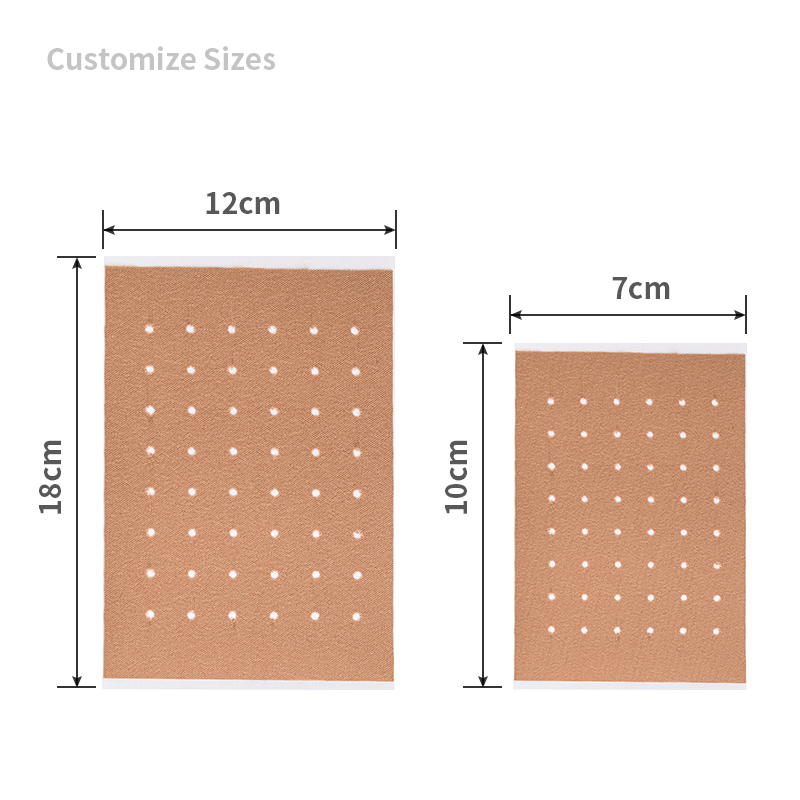

For brands looking to offer Custom Herbal Pain Relief Patches, quality control becomes even more critical. Customization often involves tweaking formulations, experimenting with new ingredients, or altering patch designs. While these changes can make a product stand out in the market, they also introduce new variables that need to be carefully managed to maintain quality.

A skilled Herbal Pain Relief Patches OEM will have the expertise to balance customization with quality control. This includes thorough testing of new formulations, ensuring that any changes do not compromise the product’s efficacy or safety. By working closely with a quality-focused OEM, brands can confidently offer customized products that meet both their specifications and the highest quality standards.

6. The Role of Technology in Quality Control

Advancements in technology have significantly enhanced quality control processes in Herbal Pain Relief Patches OEM manufacturing. Modern manufacturing facilities now employ sophisticated equipment and software to monitor every aspect of production, from the quality of raw materials to the final packaging.

For instance, automated inspection systems can detect even the smallest defects in patches, ensuring that only products meeting the strictest standards reach the market. Additionally, data analytics can help manufacturers identify trends and potential issues before they become major problems, allowing for continuous improvement in quality control processes.

Brands partnering with an Herbal Pain Relief Patches Supplier that utilizes the latest technology in quality control can be assured of receiving products that are not only of high quality but also consistently meet their specifications.

Conclusion

In the competitive market of herbal pain relief patches, quality control is not just a necessity—it’s a critical factor that can make or break a brand’s success. From ensuring product consistency and regulatory compliance to enhancing brand reputation and reducing costs, quality control plays a vital role in every aspect of Herbal Pain Relief Patches OEM manufacturing. For brands looking to offer Custom Herbal Pain Relief Patches or Private Label Herbal Pain Relief Patches, partnering with a quality-focused OEM is essential to delivering products that customers can trust.

Related Questions

Why is quality control important in Herbal Pain Relief Patches OEM manufacturing?

- Quality control ensures consistency, safety, and regulatory compliance, all of which are crucial for building customer trust and brand reputation.

How does an Herbal Pain Relief Patches Manufacturer ensure product quality?

- Through rigorous testing of raw materials, regular checks during manufacturing, and adherence to safety standards, manufacturers ensure high-quality products.

What role does technology play in quality control for Herbal Pain Relief Patches?

- Technology enhances quality control by enabling automated inspections, data analytics, and continuous monitoring of the production process.

Can customization affect the quality of Herbal Pain Relief Patches?

- Yes, customization introduces new variables that need to be carefully managed through quality control to ensure the product’s efficacy and safety are maintained.

How does quality control reduce costs in Herbal Pain Relief Patches manufacturing?

- By preventing defects and addressing issues early in the production process, quality control helps reduce waste, avoid recalls, and save costs.