The Advantages of OEM Manufacturing for Lidocaine Transdermal Patches

OEM (Original Equipment Manufacturer) manufacturing for lidocaine transdermal patches offers numerous benefits to businesses in the healthcare and pharmaceutical industries. By outsourcing production to specialized manufacturers, companies can leverage expertise, reduce costs, and improve product quality. This article explores the advantages of OEM manufacturing for lidocaine transdermal patches, emphasizing the importance of partnering with a reliable lidocaine transdermal patches manufacturer, OEM, or supplier.

1. Cost Savings

One of the most significant advantages of OEM manufacturing is cost savings. By outsourcing production, businesses can avoid the substantial capital investment required for setting up manufacturing facilities, purchasing equipment, and hiring specialized personnel. Lidocaine transdermal patches OEMs often achieve economies of scale, reducing per-unit production costs. These savings can be passed on to customers or reinvested in other areas of the business.

2. Access to Expertise and Advanced Technologies

OEM manufacturers specialize in producing specific types of products, such as lidocaine transdermal patches. This specialization means they have extensive knowledge and experience in the field, ensuring high-quality production. Additionally, OEMs invest in the latest technologies and innovations, providing their clients with access to cutting-edge manufacturing processes that enhance product efficacy and safety.

3. Customization and Flexibility

Working with a lidocaine transdermal patches OEM allows businesses to create custom lidocaine transdermal patches tailored to their specific needs. This customization can include varying dosages, patch sizes, and formulations. OEMs offer the flexibility to adapt production processes quickly to meet changing market demands or specific client requirements, ensuring that the products remain competitive and relevant.

4. Regulatory Compliance and Quality Assurance

Regulatory compliance is critical in the healthcare industry. Reputable OEM manufacturers adhere to stringent regulatory standards and quality control measures, ensuring that the products they produce are safe, effective, and compliant with all necessary regulations. This adherence protects businesses from legal and reputational risks associated with non-compliant products.

5. Reduced Time to Market

Developing and launching new products can be a time-consuming process. By partnering with a lidocaine transdermal patches OEM, businesses can significantly reduce the time to market. OEMs have established production processes and supply chains, enabling faster product development and manufacturing cycles. This speed is crucial in gaining a competitive edge and responding to market demands swiftly.

6. Focus on Core Competencies

Outsourcing production to an OEM allows businesses to focus on their core competencies, such as research and development, marketing, and sales. By leveraging the manufacturing expertise of an OEM, companies can allocate more resources and attention to activities that drive growth and innovation, enhancing overall business performance.

7. Scalability

OEM manufacturing provides businesses with the flexibility to scale production up or down based on demand. This scalability is essential for managing fluctuations in market demand and ensuring that supply meets customer needs without overcommitting resources. It also allows businesses to enter new markets or expand existing ones with minimal risk and investment.

8. Supply Chain Management

A reliable lidocaine transdermal patches supplier will have an efficient and well-managed supply chain, from sourcing raw materials to delivering finished products. This streamlined supply chain reduces the risk of delays, ensures consistent product quality, and maintains reliable inventory levels. Effective supply chain management is crucial for meeting customer expectations and maintaining a competitive market position.

9. Risk Mitigation

Manufacturing involves numerous risks, including equipment failures, regulatory issues, and production delays. By partnering with an experienced OEM, businesses can mitigate these risks. OEMs have the infrastructure, expertise, and contingency plans in place to handle potential problems, ensuring uninterrupted production and supply.

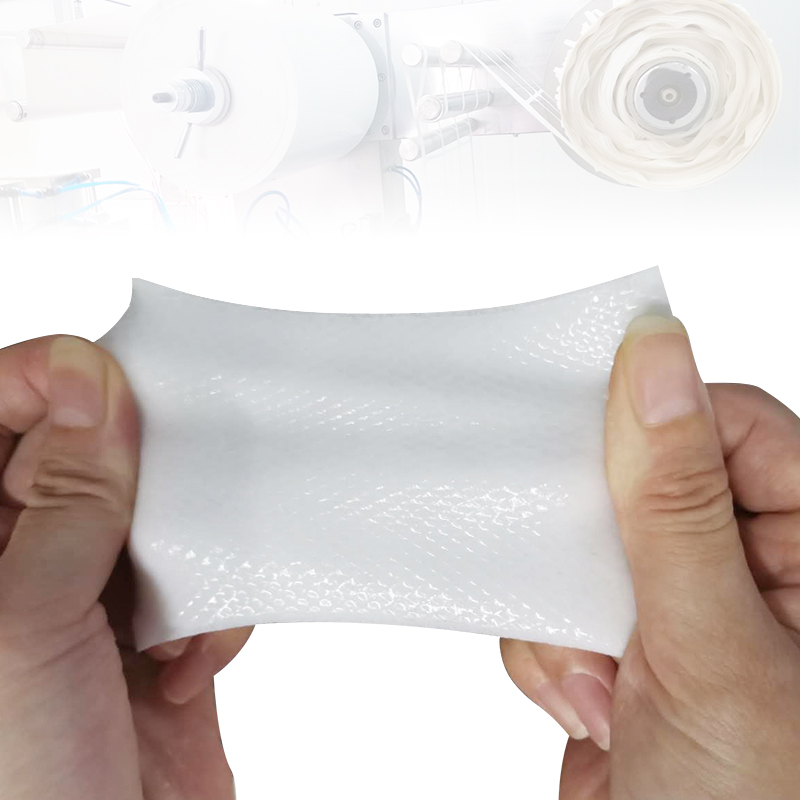

10. Enhanced Product Quality

OEM manufacturers invest in state-of-the-art equipment and adhere to best practices in production, resulting in high-quality products. For lidocaine transdermal patches, this means consistent drug delivery, reliable adhesion, and minimal side effects. High-quality products enhance customer satisfaction, improve treatment outcomes, and strengthen brand reputation.

Related Questions and Answers

What cost savings can businesses expect from OEM manufacturing of lidocaine transdermal patches?Businesses can save on capital investments, reduce per-unit production costs through economies of scale, and avoid expenses related to hiring specialized personnel and maintaining manufacturing facilities.

How does working with a lidocaine transdermal patches OEM enhance product customization?OEMs offer the flexibility to create tailored products with varying dosages, sizes, and formulations, allowing businesses to meet specific market demands and client requirements.

Why is regulatory compliance important in OEM manufacturing for lidocaine transdermal patches?Regulatory compliance ensures that products are safe, effective, and legally marketable, protecting businesses from legal and reputational risks associated with non-compliant products.

How does OEM manufacturing reduce the time to market for new products?OEMs have established production processes and supply chains, enabling faster development and manufacturing cycles, which reduces the time needed to bring new products to market.

What are the benefits of focusing on core competencies by outsourcing to a lidocaine transdermal patches OEM?Outsourcing allows businesses to allocate more resources to research, development, marketing, and sales, driving growth and innovation while leveraging the manufacturing expertise of the OEM.