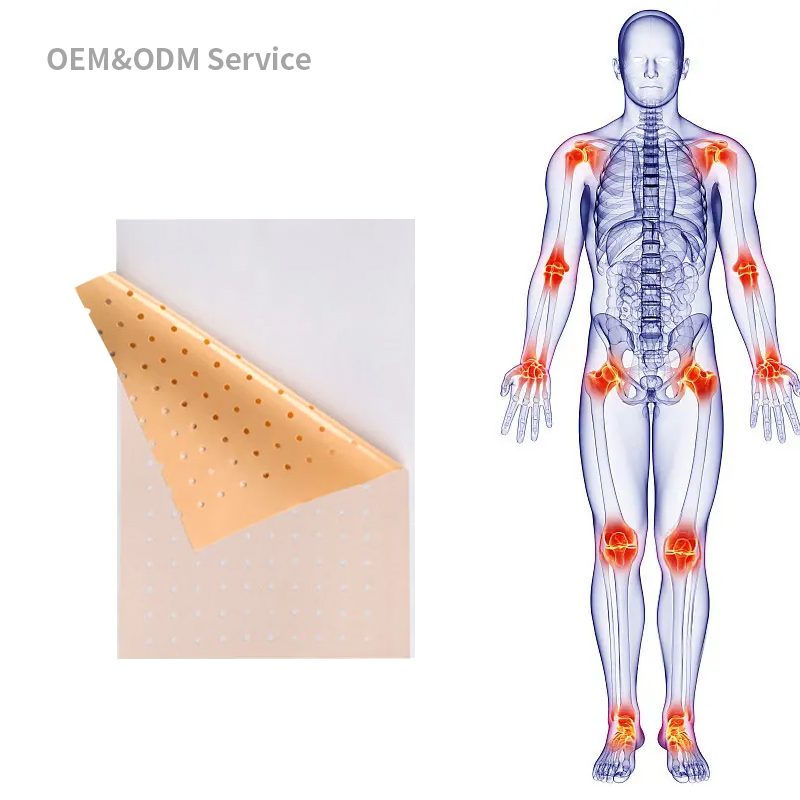

Key Considerations for OEM Partners in Customizing Capsicum Plaster

In the healthcare industry, OEM (Original Equipment Manufacturer) partnerships are pivotal in driving innovation and meeting the diverse needs of consumers. When it comes to customizing capsicum plaster, OEM partners must navigate a range of considerations to ensure product quality, safety, and market appeal. This article delves into the key considerations for OEM partners in the customization of capsicum plaster.

Understanding the Market and Target Consumers

The first step for any OEM partner in customizing capsicum plaster is to have a deep understanding of the market and target consumers. Market research is essential to identify trends, preferences, and unmet needs in the specific segment. Understanding the target consumer's pain points, lifestyle, and preferences allows OEM partners to customize the capsicum plaster to best meet their needs.

Collaborating with Capsicum Plaster Manufacturers

A successful OEM partnership hinges on close collaboration with capsicum plaster manufacturers. OEM partners must ensure that the manufacturer they choose has the necessary expertise, technology, and quality assurance measures to produce a high-quality product. Communication is key, and OEM partners should work closely with manufacturers to provide specifications, feedback, and guidance throughout the customization process.

Adhering to Regulatory Standards

Customizing capsicum plaster involves adhering to strict regulatory standards to ensure product safety and compliance. OEM partners must be aware of and comply with all relevant regulations, including those governing the packaging, labeling, ingredients, and manufacturing processes. This includes ensuring that the capsicum plaster is free from contaminants, meets safety standards, and has the necessary approvals and certifications.

Ensuring Product Quality and Safety

Product quality and safety are paramount in the healthcare industry. OEM partners must ensure that the customized capsicum plaster meets the highest standards of quality and safety. This includes rigorous testing and quality assurance measures to ensure that the product is effective, reliable, and safe for use. OEM partners should also ensure that the manufacturer has a robust quality control system and adheres to best practices in the industry.

Meeting Unique Customer Requirements

Customization often involves meeting unique customer requirements that differ from standard products. OEM partners must be flexible and innovative in meeting these requirements. This may involve customizing the formulation, packaging, labeling, or other aspects of the capsicum plaster to meet specific needs or preferences. OEM partners should work closely with their customers to understand their unique requirements and provide solutions that meet their expectations.

Branding and Marketing Considerations

Customization is often an opportunity for OEM partners to differentiate their products in the market. Branding and marketing considerations are important in this regard. OEM partners should ensure that the customized capsicum plaster aligns with their brand identity and positioning. They should also consider how the product can be marketed to target consumers effectively and efficiently.

Conclusion

Customizing capsicum plaster involves a range of considerations for OEM partners. From understanding the market and target consumers to collaborating with manufacturers, adhering to regulatory standards, ensuring product quality and safety, meeting unique customer requirements, and considering branding and marketing aspects, OEM partners must navigate a complex landscape to deliver a successful customized product. By carefully considering these key factors, OEM partners can create a customized capsicum plaster that meets the needs of their customers and positions them favorably in the market.