How to Ensure the Quality of Your Menthol Pain Relief Patches: A Comprehensive Guide

In the competitive market of pain relief products, ensuring the quality of your Menthol Pain Relief Patches is crucial. Whether you're a Menthol Pain Relief Patches manufacturer, OEM provider, or private label supplier, maintaining high standards is essential for customer satisfaction, regulatory compliance, and brand reputation. This article will guide you through the key factors that impact the quality of Menthol Pain Relief Patches, providing practical insights and industry best practices to help you deliver exceptional products.

Understanding the Importance of Quality in Menthol Pain Relief Patches

Quality is the cornerstone of any successful product. For Custom Menthol Pain Relief Patches or Private Label Menthol Pain Relief Patches, ensuring consistent quality means that customers can trust your brand, which is essential for repeat business and word-of-mouth referrals. Quality also directly impacts the efficacy of the product—poorly manufactured patches may not deliver the intended relief, leading to dissatisfied customers and potential harm.

Key Factors Affecting the Quality of Menthol Pain Relief Patches

1. Raw Material Selection

The quality of Menthol Pain Relief Patches begins with the selection of raw materials. Menthol, as the active ingredient, must be sourced from reputable suppliers who guarantee high purity levels. Inferior menthol can compromise the patch's effectiveness and safety. Additionally, the adhesives and fabric used must be skin-friendly, hypoallergenic, and durable enough to ensure the patch stays in place while allowing menthol to be gradually released.

Best Practices:

- Supplier Verification: Work with trusted Menthol Pain Relief Patches suppliers who provide certificates of analysis for their products.

- Testing: Conduct regular tests on incoming raw materials to ensure they meet your standards for purity and safety.

2. Manufacturing Processes

The manufacturing process is where the raw materials are transformed into a finished product. This step is critical in ensuring that the patches are made uniformly and consistently. Factors such as temperature control, mixing procedures, and adhesive application must be carefully monitored and controlled.

Best Practices:

- Standard Operating Procedures (SOPs): Develop and follow strict SOPs to maintain consistency across all batches.

- Quality Control Checks: Implement regular quality control checks at different stages of production to catch any defects early.

3. Quality Control and Testing

Comprehensive quality control is essential for identifying any issues that could compromise the product's performance or safety. This includes testing the patches for menthol content, adhesion strength, and release rate. Additionally, it is important to conduct stability testing to ensure that the patches remain effective over their shelf life.

Best Practices:

- Batch Testing: Test every batch of patches for key performance indicators such as menthol content and adhesion.

- Stability Testing: Conduct long-term stability tests under various conditions to ensure product efficacy over time.

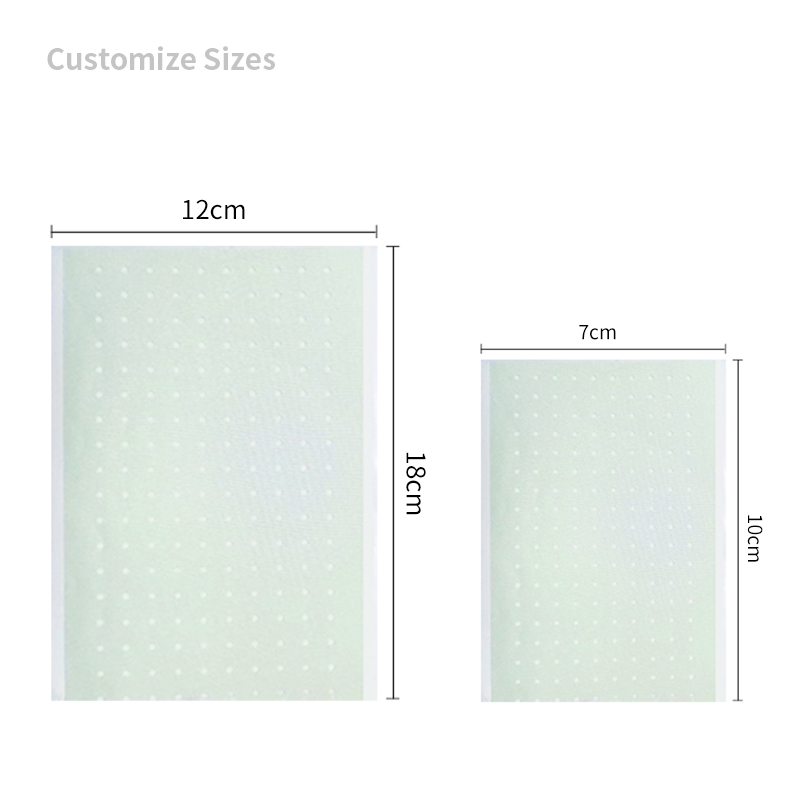

4. Packaging and Storage

The packaging of Menthol Pain Relief Patches plays a vital role in maintaining their quality. Proper packaging protects the patches from environmental factors such as moisture and light, which can degrade menthol. The packaging must also be easy to use, ensuring that consumers can apply the patches without compromising their integrity.

Best Practices:

- Protective Packaging: Use high-quality, airtight packaging materials that prevent moisture and light exposure.

- Storage Conditions: Store patches in a cool, dry place to preserve their effectiveness.

5. Regulatory Compliance

Compliance with regulatory standards is non-negotiable. Regulatory bodies such as the FDA have strict guidelines for the manufacture and labeling of pain relief patches. Non-compliance can result in fines, product recalls, and damage to your brand's reputation.

Best Practices:

- Stay Informed: Keep up-to-date with the latest regulatory requirements in your region.

- Documentation: Maintain detailed records of all manufacturing processes, quality control tests, and supplier information to demonstrate compliance.

6. Customer Feedback and Continuous Improvement

Finally, quality assurance doesn't end when the product leaves the factory. Gathering customer feedback is an invaluable tool for continuous improvement. Complaints or issues should be taken seriously and used to refine the manufacturing process or improve product design.

Best Practices:

- Customer Surveys: Regularly survey customers to gauge satisfaction and identify any issues with the product.

- Issue Resolution: Develop a robust process for addressing and resolving customer complaints quickly and effectively.

Frequently Asked Questions (FAQs)

1. What should I look for when choosing a Menthol Pain Relief Patches supplier?

- Look for suppliers with a proven track record, who can provide high-quality raw materials with certificates of analysis.

2. How can I ensure my Custom Menthol Pain Relief Patches meet regulatory standards?

- Stay informed about local and international regulations and implement comprehensive documentation practices to demonstrate compliance.

3. What testing should be conducted on Private Label Menthol Pain Relief Patches?

- Conduct batch testing for menthol content, adhesion strength, and release rate, along with long-term stability tests.

4. How important is packaging in maintaining the quality of Menthol Pain Relief Patches?

- Packaging is crucial; it protects the patches from environmental factors that can degrade their effectiveness.

5. What role does customer feedback play in quality assurance?

- Customer feedback is essential for continuous improvement and helps identify areas where the product or process can be improved.

Conclusion

Ensuring the quality of your Menthol Pain Relief Patches is an ongoing process that requires attention to detail at every stage, from raw material selection to manufacturing, packaging, and beyond. Whether you are a Menthol Pain Relief Patches manufacturer, OEM provider, or private label supplier, adhering to best practices and maintaining strict quality control will help you deliver a product that meets customer expectations and stands out in the market. By following these guidelines, you can build a reputation for reliability and effectiveness that will drive your business's success.