How to Choose the Best OEM Partner for Knee Pain Relief Patches: A Comprehensive Guide

In the fast-growing health and wellness market, knee pain relief patches have emerged as a popular and convenient solution for individuals seeking non-invasive pain management. As a brand looking to tap into this lucrative segment, partnering with the right Original Equipment Manufacturer (OEM) for your custom knee pain relief patches is crucial. This guide outlines a step-by-step approach to selecting the best OEM partner, ensuring your product stands out in quality, efficacy, and market appeal.

1. Define Your Product Requirements

a. Understand Your Target Audience: Start by identifying your ideal customer's needs, preferences, and pain points. Are they athletes recovering from injuries? Seniors managing chronic knee pain? Or individuals seeking natural alternatives to medication?

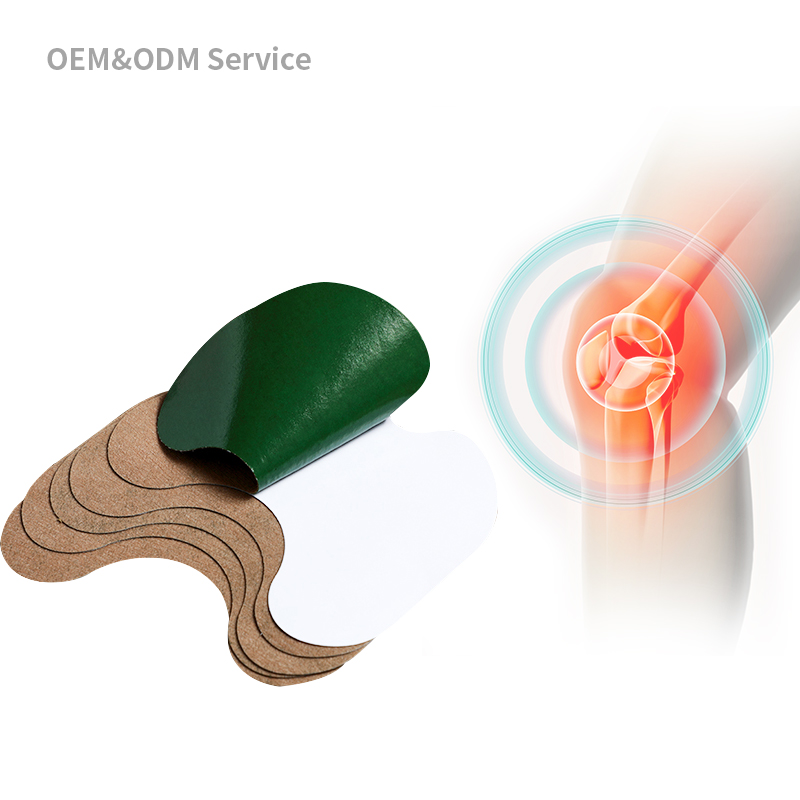

b. Specify Product Features: Based on your audience, outline the must-have features for your knee pain relief patches. Consider factors like active ingredients (e.g., menthol, arnica, or CBD), patch size and shape, adhesive strength, and duration of relief.

c. Determine Customization Needs: Decide if you require custom formulations, packaging designs, or private labeling services. This will help narrow down your OEM options.

2. Research OEM Candidates

a. Search for Reputable Manufacturers: Utilize industry directories, online platforms like Alibaba or Thomasnet, and referrals from industry peers to compile a list of potential OEM partners specializing in knee pain relief patches.

b. Check Credentials and Certifications: Verify if the manufacturers are compliant with relevant regulations (e.g., FDA, CE, ISO) and have a proven track record of producing high-quality products.

c. Review Product Portfolios: Examine their existing product lines to assess their expertise in formulating and manufacturing knee pain relief patches. Look for similar projects they've undertaken and their success stories.

3. Evaluate Capabilities and Expertise

a. Technical Expertise: Ensure the OEM has a strong R&D team capable of developing custom formulations tailored to your specific requirements.

b. Manufacturing Capabilities: Inquire about their production capacity, equipment, and processes. A modern, automated facility indicates efficiency and scalability.

c. Quality Control: Ask about their quality assurance procedures, including raw material sourcing, in-process testing, and final product inspection.

d. Regulatory Compliance: Verify their understanding of regulatory requirements for your target markets and their ability to provide necessary documentation.

4. Compare Pricing and Services

a. Cost Analysis: Request detailed quotes that include raw material costs, manufacturing fees, customization charges, and shipping expenses. Compare these against your budget and market positioning.

b. Services Offered: Assess the OEM's willingness to provide additional services like product design, packaging customization, regulatory support, and marketing assistance.

c. Flexibility and Responsiveness: Evaluate their ability to adapt to changes, such as design revisions or production schedule adjustments.

5. Establish Communication and Negotiate Terms

a. Clear Communication: Ensure open and transparent communication channels are established from the onset. Discuss expectations, timelines, and potential challenges openly.

b. Contract Negotiation: Draft a comprehensive agreement that covers all aspects of the partnership, including intellectual property rights, payment terms, delivery schedules, and dispute resolution mechanisms.

c. Samples and Testing: Request product samples for evaluation and third-party testing to verify claims and ensure customer satisfaction.

6. Monitor and Maintain the Partnership

a. Continuous Quality Control: Establish a system to monitor product quality throughout the production cycle. Regular audits and inspections can help maintain standards.

b. Market Feedback: Collect and analyze customer feedback to identify areas for improvement and share this information with your OEM partner.

c. Flexibility for Growth: As your brand grows, discuss potential expansions or modifications to the partnership to accommodate new product lines or market demands.

Related Questions and Answers

Q1: What are the key factors to consider when choosing a Knee Pain Relief Patches OEM partner?

A: Key factors include technical expertise, manufacturing capabilities, quality control procedures, regulatory compliance, pricing, and services offered.

Q2: How can I ensure the quality of my custom knee pain relief patches?

A: By partnering with an OEM that adheres to strict quality assurance procedures, sourcing high-quality raw materials, and undergoing regular third-party testing.

Q3: What role does communication play in a successful OEM partnership?

A: Clear and open communication is vital for setting expectations, addressing challenges, and ensuring a smooth production process. Regular updates and feedback loops strengthen