How Important is Quality Control When Choosing a Deep Heat Patches Supplier?

Quality control is essential in the manufacturing and supply of health and wellness products like deep heat patches. With the increasing demand for effective pain relief solutions, choosing the right Deep Heat Patches Supplier is critical to ensure safe, high-quality products. Quality control not only ensures that Custom Deep Heat Patches are effective but also safeguards consumer health and builds brand credibility. In this article, we will explore the importance of quality control in the production process, the role of a Deep Heat Patches Manufacturer in maintaining standards, and how quality assurance impacts brand success.

1. The Role of Quality Control in Deep Heat Patches Manufacturing

Quality control is the systematic process by which manufacturers ensure that every Deep Heat Patch meets specific standards. It involves multiple steps, from ingredient sourcing to production and final testing, each designed to maintain consistency, effectiveness, and safety.

Key Areas of Quality Control

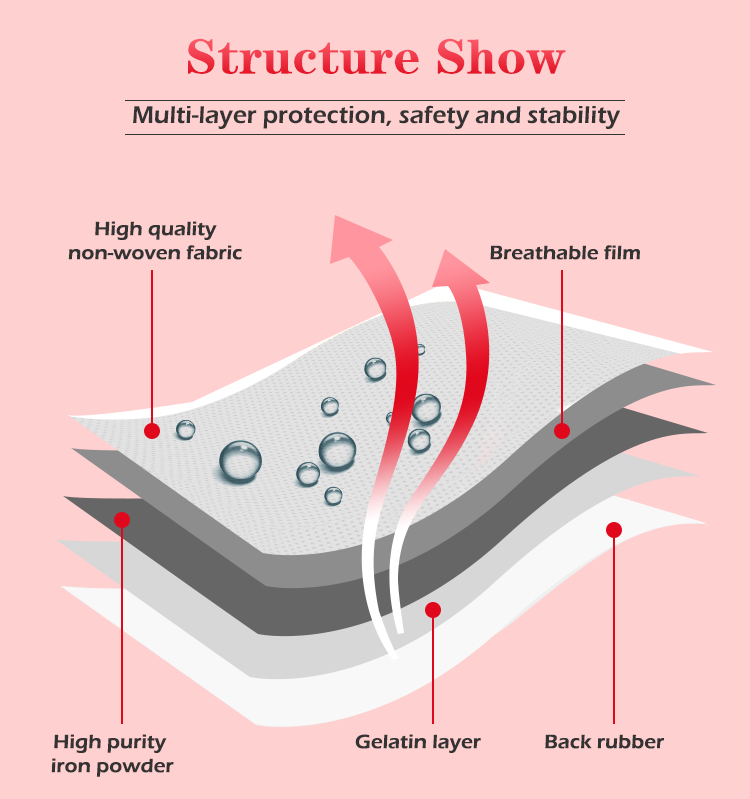

- Ingredient Selection and Testing: Each ingredient used in a deep heat patch, such as iron powder and activated charcoal, must meet purity and safety requirements.

- Manufacturing Standards: Manufacturers follow strict protocols to ensure uniformity across batches, meaning each patch performs the same way for every customer.

- Post-Production Testing: Patches undergo rigorous testing to verify their adherence to safety and efficacy standards, including heat duration, skin adhesion, and potential irritants.

In choosing a Deep Heat Patches OEM, a company’s commitment to quality control is vital for delivering safe products that meet regulatory standards.

2. Quality Control in Custom Deep Heat Patches

With Custom Deep Heat Patches, brands offer unique formulations tailored to specific customer needs, which makes quality control even more essential. Customization introduces variability that requires more meticulous quality control measures to ensure product consistency.

Importance of Quality Control in Customization

- Maintaining Consistency Across Custom Batches: Custom products must be consistent across batches, despite potential changes in formulation or size. Quality control ensures that each batch of Custom Deep Heat Patches aligns with the brand’s standards.

- Safety Assurance in Ingredient Modification: When creating customized patches, manufacturers might adjust the ratios of active ingredients to deliver varied heat levels. Each change must be tested to confirm that it doesn’t compromise user safety or patch effectiveness.

- Meeting Regulatory Compliance for Different Markets: Customized patches may be intended for different regions, each with its own regulatory standards. A reputable Deep Heat Patches Manufacturer ensures that all products meet the relevant guidelines, regardless of customization.

3. The Role of Quality Control in Private Label Deep Heat Patches

Private labeling offers companies the chance to sell high-quality deep heat patches under their own brand names without investing in full-scale manufacturing. A reliable Deep Heat Patches Supplier upholds strict quality control measures to ensure that Private Label Deep Heat Patches meet industry standards and are ready for consumer use.

Benefits of Quality Control in Private Labeling

- Building Consumer Trust: Consumers rely on Private Label Deep Heat Patches for relief and comfort, and quality control ensures consistent product performance that builds brand trust.

- Reducing Liability Risks: Rigorous quality control helps prevent faulty batches, reducing the risk of recalls, customer complaints, and potential legal issues.

- Competitive Advantage: A supplier with a strong reputation for quality control gives brands a competitive edge by ensuring high-performance products that consumers can trust.

Working with a Deep Heat Patches OEM that emphasizes quality control not only mitigates risks but also enhances the brand’s reputation.

4. How a Deep Heat Patches Supplier Ensures Quality Control

A reliable Deep Heat Patches Supplier invests in advanced quality control processes and equipment. The supplier’s expertise in quality assurance directly affects product safety and consistency, impacting both consumer satisfaction and brand loyalty.

Key Quality Control Processes in Deep Heat Patch Production

- Raw Material Testing: High-quality suppliers test all incoming raw materials to ensure they meet specific safety and performance standards. This initial testing prevents impurities that could reduce the efficacy or safety of the patches.

- In-Process Quality Checks: Quality control doesn’t stop with raw materials; it continues throughout the production process. In-process checks ensure that each patch meets design specifications and that each batch is uniform.

- Finished Product Testing: Once a batch is complete, each patch undergoes thorough testing for temperature regulation, adhesion, and skin compatibility. Finished product testing ensures that every patch offers reliable heat levels without risking user discomfort or skin irritation.

- Storage and Packaging Standards: Quality control also extends to packaging, as improper storage can impact product effectiveness. Deep Heat Patches are sensitive to environmental factors like humidity, so packaging must meet specific standards to preserve product quality.

5. The Impact of Quality Control on Brand Success

The importance of quality control in manufacturing cannot be overstated. Brands that partner with a reputable Deep Heat Patches Manufacturer gain access to high-quality products, while consumers enjoy effective pain relief solutions they can trust. Quality control is integral to a brand's reputation, customer satisfaction, and long-term growth.

Consumer Loyalty and Brand Trust

When consumers trust the quality and safety of a brand’s deep heat patches, they are more likely to become repeat customers. Quality control gives consumers confidence that each patch will provide the expected relief, strengthening brand loyalty.

Risk Mitigation

Poor quality control can result in defective products, leading to potential health risks for users. Brands that prioritize quality reduce the likelihood of product recalls or safety concerns, avoiding damage to brand reputation and additional costs.

Meeting Regulatory Compliance

Adherence to regulatory standards is essential for any health-related product. By choosing a supplier committed to rigorous quality control, brands ensure their Private Label Deep Heat Patches or Custom Deep Heat Patches meet local and international safety regulations, preventing legal issues and enhancing credibility.

Conclusion

Quality control is crucial when selecting a Deep Heat Patches Supplier. From sourcing pure ingredients to ensuring consistency across batches, quality control protects consumers, enhances brand reputation, and reduces risks associated with faulty products. Brands offering Custom Deep Heat Patches or Private Label Deep Heat Patches must partner with a Deep Heat Patches OEM that prioritizes quality assurance at every stage. Ultimately, quality control ensures that every patch delivers safe, reliable heat for effective pain relief, which is essential for building long-term brand trust and consumer satisfaction.

Frequently Asked Questions

1. Why is quality control important for Deep Heat Patches?

Quality control ensures that each patch meets safety and performance standards, providing effective and reliable pain relief for consumers.

2. How can I tell if a Deep Heat Patches Supplier prioritizes quality?

Look for suppliers with certifications like ISO, FDA approval, or CE marking, which indicate that their products meet specific safety and quality standards.

3. What role does a Deep Heat Patches OEM play in quality control?

A Deep Heat Patches OEM is responsible for quality assurance across all stages, from ingredient sourcing to post-production testing, ensuring consistent results for each patch.

4. Are Custom Deep Heat Patches more prone to quality issues?

No, as long as the manufacturer has stringent quality control processes in place. Customization simply requires additional testing to ensure each custom batch meets quality standards.

5. How does quality control affect Private Label Deep Heat Patches?

For private label products, quality control is essential for brand reputation, as it ensures consistent performance and safety, leading to higher customer satisfaction and trust.

Choosing a Deep Heat Patches Supplier with a strong emphasis on quality control is a wise investment for any brand seeking to build a trusted, effective product line in the competitive pain-relief market.