How Do OEM Manufacturers Ensure the Quality of Guarana Slimming Patches?

The increasing demand for slimming products, particularly those utilizing natural ingredients like guarana, has led many businesses to explore opportunities in the health and wellness market. Guarana Slimming Patches have become a popular choice for consumers seeking an effective, non-invasive weight loss solution. For businesses looking to offer Custom Guarana Slimming Patches or Private Label Guarana Slimming Patches, ensuring product quality is critical to success. This is where the role of an OEM (Original Equipment Manufacturer) becomes crucial.

An OEM Guarana Slimming Patches Manufacturer not only produces the product but also ensures that it meets stringent quality standards. In this article, we’ll explore how OEM manufacturers ensure the quality of Guarana Slimming Patches, and why partnering with a reliable Guarana Slimming Patches Supplier is essential for building consumer trust and achieving long-term success.

1. Stringent Ingredient Sourcing and Testing

The quality of Guarana Slimming Patches starts with the raw materials. Guarana, a natural stimulant known for its metabolism-boosting properties, must be sourced from reputable suppliers to ensure its potency and purity. Guarana Slimming Patches OEMs carefully select and vet their guarana suppliers to guarantee the ingredient’s quality.

Once sourced, the raw materials undergo rigorous testing. This includes checks for contaminants such as heavy metals, pesticides, and microbiological impurities. These tests ensure that only high-quality guarana extract is used in the production process, safeguarding both the effectiveness and safety of the final product.

Furthermore, OEMs may conduct additional tests on other ingredients used in Custom Guarana Slimming Patches, such as adhesives, stabilizers, and complementary herbal extracts. By ensuring the purity and efficacy of all components, the Guarana Slimming Patches Manufacturer can produce a superior product that meets industry standards.

2. Adherence to Good Manufacturing Practices (GMP)

One of the most critical factors in ensuring product quality is adherence to Good Manufacturing Practices (GMP). These are internationally recognized guidelines that ensure products are consistently produced and controlled according to quality standards. A Guarana Slimming Patches Manufacturer operating under GMP guidelines guarantees that the production process is safe, efficient, and reliable.

GMP covers all aspects of production, from the cleanliness of facilities to the training of staff and the handling of materials. By adhering to GMP, OEM manufacturers prevent contamination, mix-ups, and errors in production. This means that every batch of Private Label Guarana Slimming Patches will have the same high level of quality, ensuring consistency and reliability for consumers.

3. Advanced Manufacturing Technology

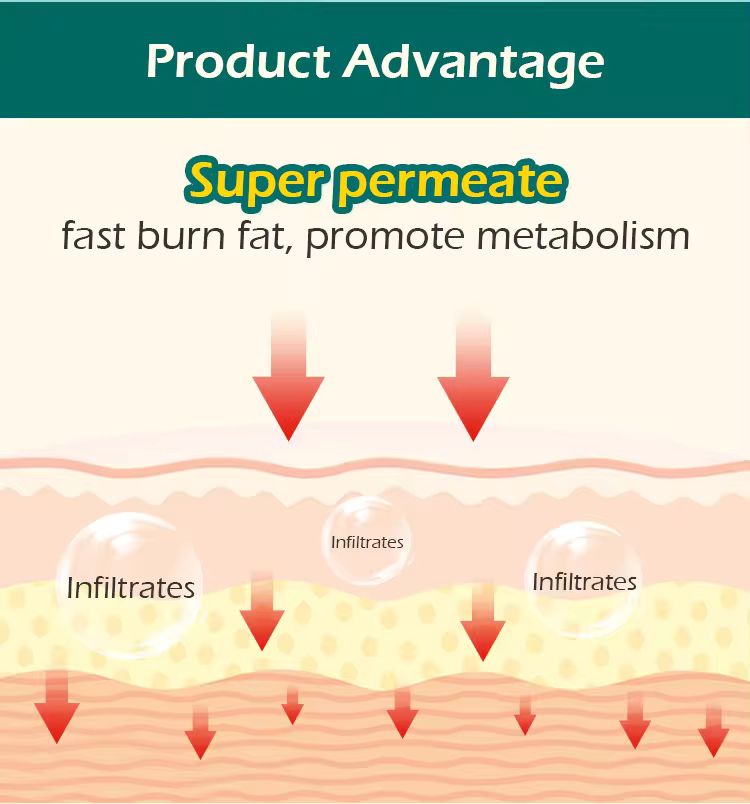

Guarana Slimming Patches OEMs use advanced manufacturing technologies to ensure precision and quality throughout the production process. This includes the use of automated systems that control factors such as temperature, pressure, and adhesive application during the production of the patches. By utilizing state-of-the-art technology, OEM manufacturers minimize the risk of human error and improve the overall consistency of the product.

The adhesive technology used in slimming patches is particularly important, as it ensures that the patch stays in place on the skin and delivers the active ingredients effectively. Guarana Slimming Patches Suppliers invest in research and development to create adhesive formulas that are not only skin-friendly but also capable of releasing the active ingredients steadily over time, maximizing their slimming benefits.

4. Comprehensive Product Testing

Before any batch of Custom Guarana Slimming Patches is released to the market, it undergoes comprehensive testing to ensure it meets the required quality standards. These tests can include:

Stability Testing: To ensure that the patches maintain their effectiveness and safety over time, stability testing is conducted to simulate long-term storage conditions. This ensures that the patches remain potent and effective even after prolonged shelf life.

Adhesion Testing: The patches must adhere properly to the skin for a specified duration. Guarana Slimming Patches Manufacturers conduct adhesion tests to confirm that the patches will remain in place for the necessary amount of time without causing irritation or discomfort.

Absorption Testing: To verify that the active ingredients, particularly guarana, are absorbed into the body as intended, OEM manufacturers conduct absorption tests. These tests confirm that the patches deliver the correct dosage of guarana and other active ingredients through the skin, ensuring the product’s effectiveness.

Dermatological Testing: To ensure that the patches are safe for use on the skin, Guarana Slimming Patches Suppliers conduct dermatological tests. This helps to identify and address any potential skin reactions, ensuring that the product is safe for all skin types.

5. Quality Control Throughout the Production Process

Quality control doesn’t just happen at the end of the production process. A reliable Guarana Slimming Patches OEM implements quality control measures at every stage of manufacturing. This includes monitoring the blending of ingredients, the application of adhesives, and the cutting and packaging of the patches.

OEM manufacturers often have a dedicated quality control team that oversees each stage of production, ensuring that any deviations from the standard are immediately addressed. This proactive approach minimizes the risk of defective products and ensures that only patches meeting the highest standards are delivered to customers.

6. Compliance with Regulatory Standards

In addition to following GMP guidelines, Guarana Slimming Patches Manufacturers must comply with local and international regulatory standards. These regulations are put in place to ensure that products are safe for consumers and meet all necessary quality requirements. For example, manufacturers may need to adhere to regulations set by the FDA (Food and Drug Administration) in the United States or the European Medicines Agency (EMA) in Europe.

By ensuring compliance with these regulatory standards, OEM manufacturers can offer products that are not only effective but also safe for use. This compliance is essential for gaining the trust of consumers and retailers, as well as for ensuring that the product can be sold in various markets around the world.

7. Continuous Improvement Through R&D

The best Guarana Slimming Patches Suppliers invest in continuous research and development (R&D) to improve product quality and effectiveness. Through R&D, OEM manufacturers can develop new formulations, improve adhesive technology, and explore innovative delivery systems that make slimming patches more effective and user-friendly.

For businesses offering Private Label Guarana Slimming Patches, this commitment to innovation means that they can continually offer cutting-edge products that meet the evolving needs of their customers. Whether it’s developing patches with faster absorption rates or creating eco-friendly alternatives, OEM manufacturers play a critical role in driving product improvements and maintaining high quality.

8. Traceability and Transparency

OEM manufacturers often implement traceability systems to track the origin and handling of raw materials used in Custom Guarana Slimming Patches. This transparency allows businesses to ensure that their products meet the required ethical and environmental standards, which is increasingly important to consumers.

By providing transparency in sourcing and manufacturing practices, Guarana Slimming Patches Manufacturers build trust with both businesses and end consumers. This is particularly important for companies that want to market their products as natural, sustainable, or ethically produced.

Related Questions and Answers

1. How do OEM manufacturers ensure the effectiveness of Guarana Slimming Patches?

- OEM manufacturers ensure effectiveness through ingredient sourcing, comprehensive testing, and advanced absorption technologies that maximize the slimming effects of guarana.

2. What role does GMP play in the quality of Guarana Slimming Patches?

- GMP (Good Manufacturing Practices) ensures that the production of slimming patches is controlled, consistent, and free from contamination, resulting in a high-quality product.

3. Can I customize my Guarana Slimming Patches for different skin types?

- Yes, working with a Guarana Slimming Patches OEM allows you to create custom formulations that cater to different skin types and sensitivities.

4. How do OEM manufacturers test the safety of slimming patches?

- Safety is ensured through dermatological testing, stability testing, and absorption studies, all of which confirm that the patches are safe and effective for consumer use.

5. What standards must Guarana Slimming Patches Manufacturers follow?

- Manufacturers must follow GMP guidelines and comply with regulatory standards such as those set by the FDA or EMA to ensure product safety and quality.

In conclusion, partnering with a reliable Guarana Slimming Patches OEM is crucial for businesses looking to offer high-quality, effective slimming patches. From ingredient sourcing to comprehensive testing and regulatory compliance, OEM manufacturers play a key role in ensuring that Private Label Guarana Slimming Patches meet the highest standards, helping your business build trust, improve market competitiveness, and deliver results to customers.