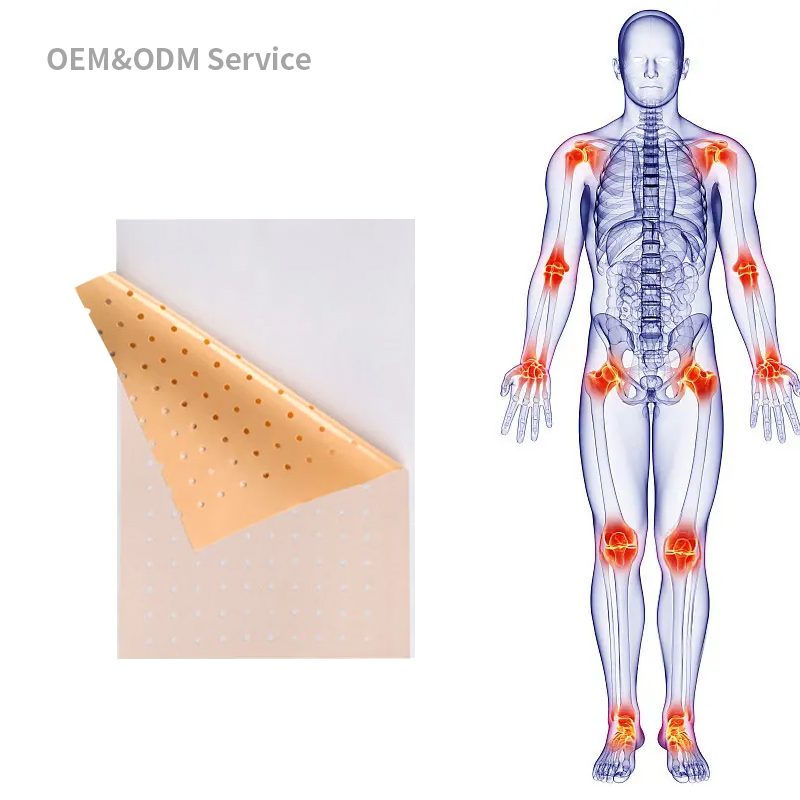

Evaluating the Cost-Effectiveness of a Capsicum Plaster Manufacturer for OEM Partnerships

When an Original Equipment Manufacturer (OEM) partner is considering a partnership with a Capsicum Plaster manufacturer, evaluating the cost-effectiveness of the potential collaboration is crucial. This evaluation process should be comprehensive, considering various factors that can impact the long-term success of the partnership. Here's a detailed discussion of some of the key factors that OEM partners should take into account.

1. Production Capacity and Efficiency

The first factor to consider is the production capacity and efficiency of the Capsicum Plaster manufacturer. A cost-effective manufacturer should be able to meet the OEM's demand, both in terms of quantity and quality. Additionally, they should have a high level of production efficiency, minimizing waste and maximizing output. This can be assessed by reviewing the manufacturer's production processes, equipment, and staff training.

2. Quality Control and Compliance

The quality of the Capsicum Plaster products is essential for the OEM's reputation and brand image. Therefore, it's important to ensure that the manufacturer has robust quality control measures and complies with all relevant regulations and standards. This includes ensuring that the raw materials used are of high quality, the manufacturing process is well-controlled, and the finished products undergo rigorous testing before shipment.

3. Cost Analysis

A detailed cost analysis is crucial for evaluating the cost-effectiveness of a Capsicum Plaster manufacturer. OEM partners should request a breakdown of costs, including raw materials, labor, overheads, and any other relevant expenses. This will help them understand where the manufacturer's costs are incurred and identify any potential areas for cost reduction or negotiation.

4. Flexibility and Customization

OEM partners often require customized Capsicum Plaster products to meet their specific needs. Therefore, it's important to assess the manufacturer's flexibility and ability to customize products. A cost-effective manufacturer should be able to provide customized solutions within a reasonable timeframe and at a competitive price.

5. Delivery and Logistics

Efficient delivery and logistics are essential for maintaining a smooth supply chain. OEM partners should evaluate the manufacturer's delivery capabilities, including their ability to meet deadlines, handle large orders, and provide tracking and tracing facilities. Additionally, they should consider the cost of shipping and any additional fees that may be incurred during transportation.

6. Reputation and References

The reputation and references of a Capsicum Plaster manufacturer can provide valuable insights into their performance and reliability. OEM partners should research the manufacturer's history, customer reviews, and any industry awards or certifications they have received. Additionally, they can request references from other OEM partners who have worked with the manufacturer to get a firsthand account of their experience.

7. After-Sales Support

After-sales support is an important aspect of any partnership. OEM partners should evaluate the manufacturer's after-sales support policies, including their ability to handle product returns, repairs, and replacements. A cost-effective manufacturer should provide comprehensive after-sales support that minimizes downtime and disruption to the OEM's business operations.

Conclusion

Evaluating the cost-effectiveness of a Capsicum Plaster manufacturer for an OEM partnership requires a comprehensive analysis of various factors. By considering production capacity and efficiency, quality control and compliance, cost analysis, flexibility and customization, delivery and logistics, reputation and references, and after-sales support, OEM partners can make an informed decision that will lead to a successful and profitable partnership.

Related Questions and Answers

Q1: How do I assess the quality of a Capsicum Plaster manufacturer?

A1: You can assess the quality of a Capsicum Plaster manufacturer by reviewing their quality control measures, compliance with regulations, and customer reviews. Additionally, you can request samples of their products to evaluate the quality directly.

Q2: What are the key factors to consider when evaluating the cost-effectiveness of a manufacturer?

A2: The key factors to consider when evaluating the cost-effectiveness of a manufacturer include production capacity and efficiency, quality control, cost analysis, flexibility and customization, delivery and logistics, reputation, and after-sales support.

Q3: How can I ensure that a manufacturer can meet my customized product requirements?

A3: You can ensure that a manufacturer can meet your customized product requirements by evaluating their flexibility and ability to provide customized solutions. Request samples or prototypes of your customized products to verify their capabilities.

Q4: What role does reputation play in evaluating a manufacturer?

A4: Reputation is an important factor to consider when evaluating a manufacturer. A good reputation indicates that the manufacturer has a proven track record of delivering quality products and services to their customers. Additionally, good references from other OEM partners can provide valuable insights into the manufacturer's performance and